Examine This Report about Motorcycle Parts New Zealand Specialists

Table of ContentsGetting The Motorcycle Parts New Zealand Specialists To WorkMotorcycle Parts New Zealand Specialists Can Be Fun For EveryoneMotorcycle Parts New Zealand Specialists Can Be Fun For AnyoneThe Motorcycle Parts New Zealand Specialists DiariesThe Only Guide to Motorcycle Parts New Zealand SpecialistsMore About Motorcycle Parts New Zealand SpecialistsThe smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking AboutSome Known Factual Statements About Motorcycle Parts New Zealand Specialists

So, get to out to one of our specialists today.CNC machining technology is swiftly becoming the focal point of several different manufacturing processes around the world as a straight result of its several benefits over various other methods. Furthermore, the sectors that produce motorbikes have actually gotten on board with this fad. The most ingenious companies are now establishing their engine elements and wheels utilizing machining methods initially developed for motorcycle parts.

You may be wondering why we make use of. Currently that we have your interest allow us explain the reasoning behind this modern growth in the motorcycle manufacturing market.

The 6-Second Trick For Motorcycle Parts New Zealand Specialists

In enhancement, you have full control over the appearance of the parts, also down to the min details. Occasionally, motorcyclists might determine to spruce up their trip by mounting aftermarket components or customizing the bike's transformation.

Motorcycle Parts New Zealand Specialists Things To Know Before You Buy

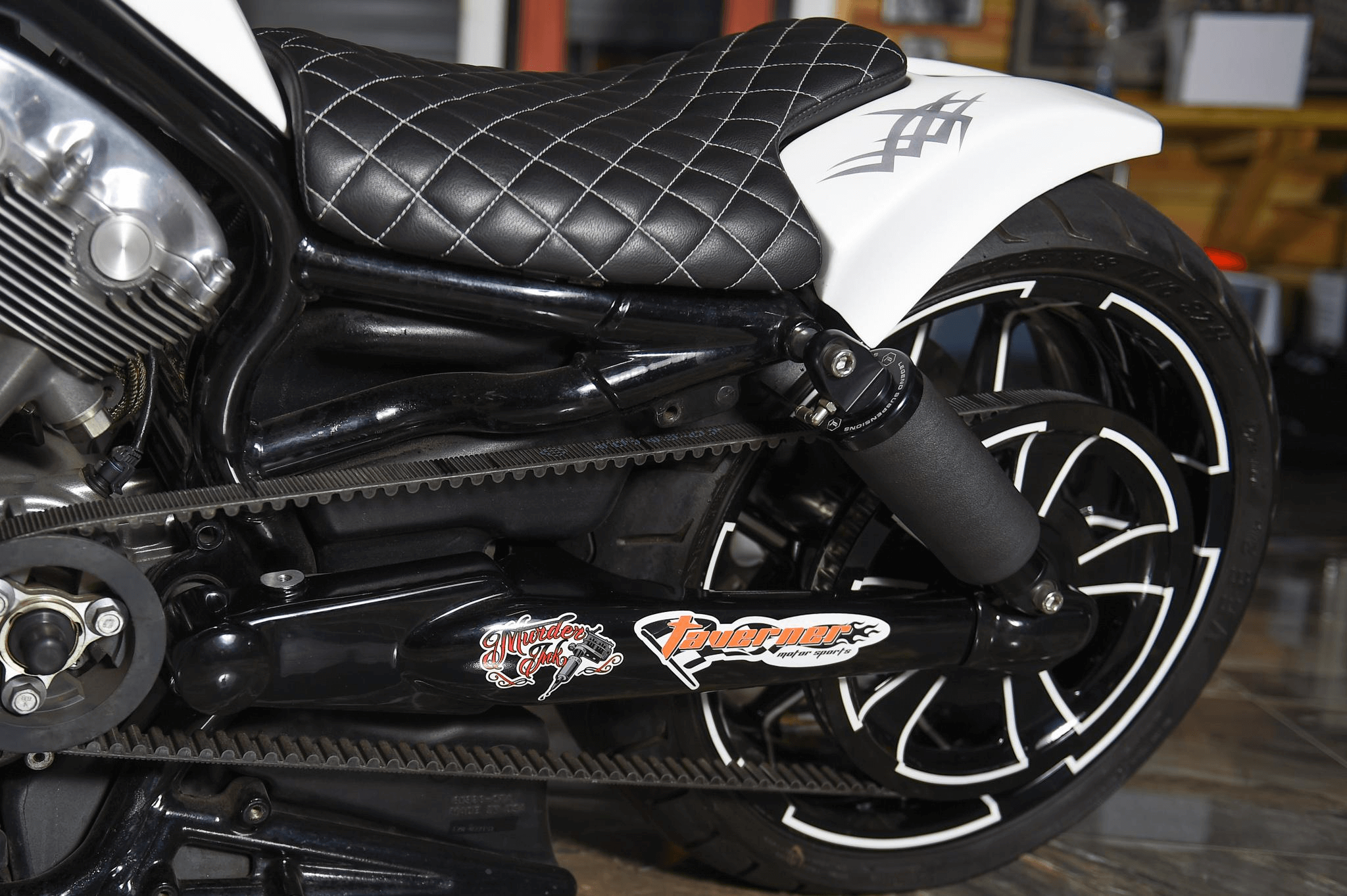

CNC machining might be utilized to make practically all of a bike's steel and plastic elements. To continue, we'll go over numerous machined parts for motorcycles. Unlike those on autos, wheels on bikes tend to be extra apparent. As a result, the bike's looks may be enhanced with the proper customization of these wheels.

When tailoring the wheels, the disks are where the emphasis must be. Most of them are constructed of aluminum. Aluminum alloys are widely known for the superior machining abilities that they possess. Milling procedures are used to get the desired level of wheel personalization. An additional element of the motorbike that might be customized is the tires.

Getting The Motorcycle Parts New Zealand Specialists To Work

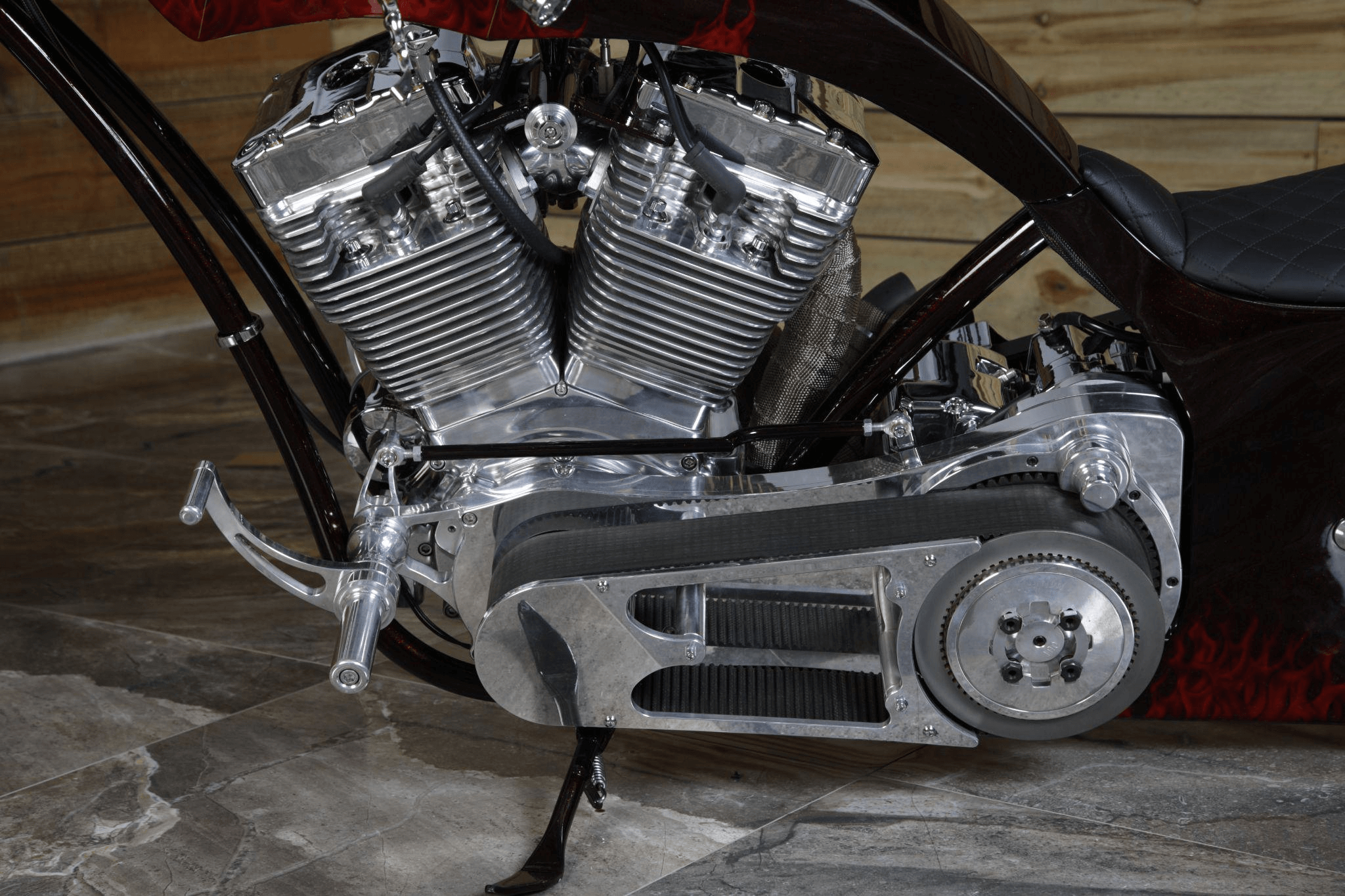

When it pertains to a vehicle (or a motorcycle), the most essential component is the engine. Numerous individuals mention it as the "heart" of the car. On the other hand, the camshaft, the cylinder head, and the pistons tend to be complex and require styles with a high degree of precision.

Illumination is an additional facility aspect of customization. Usage just top notch items, nevertheless, considering that these lights are important for the security of motorcyclists and other drivers or individuals when traveling, especially in the evening. Motorcycle headlights have 3 major components: the bulb, or light resource, the lens, and the real estate. Specifically, we customize the lens and the real estate.

Milling procedures with a remarkable find out here coating would certainly result in the lenses having a reflective high quality that resembles that of a mirror. The cover, on the various other hand, is not composed of breakable products; instead, it is constructed out of difficult polymers that can be machined into even more complex patterns.

Motorcycle Parts New Zealand Specialists Can Be Fun For Everyone

They often have sophisticated geometries with a wide range of min details. Motorcycle suppliers usually cast these elements, however just for the production of bespoke components. However, CNC machining is the technique of selection when producing one-of-a-kind pieces. Machining on five axes in today's globe is the means whereby any kind of layout shape might be realized.

Select Runsom for your tailored motorcycle parts! We have the capacity to fabricate complex and stylish parts making your motorcycle incomparable.

Right here are a couple of instances of steels frequently utilized in motorbike element machining. Light weight aluminum is the main product made use of by companies specializing in generating custom motorbike elements to create a lot of these components. In the past, we would build our engines out of cast iron. On the various other hand, aluminum is rapidly coming to be the material of option, partly as a result of the truth that it is more lightweight.

Zinc refers to an additional metal that is extremely light in weight and has excellent machining top qualities because of its high mechanical stamina. This material might be formed right into nearly any type of shape and maintains its measurements well. Even mission-critical components that require a high level of accuracy might benefit from their use.

All about Motorcycle Parts New Zealand Specialists

An additional metal that sees hefty usage in the manufacturing of CNC-customized parts is magnesium. It is among the lightest steels that are now easily accessible and has exceptional machinability features and stamina commensurate with its low weight. Among the drawbacks of magnesium is that its our website dust may easily ignite.

Because of its premium machinability and weldability, stainless steel is an alloy that is especially fit for CNC procedures. In addition to this, they have terrific deterioration resistance and a high aesthetic appeal. Their most common use in producing various motorcycle parts is bolts, such as screws and bolts. Their low vulnerability to oxidation and deterioration makes them ideal for this use.

The 6-Minute Rule for Motorcycle Parts New Zealand Specialists

It appears that CNC turning and crushing are the foundational procedures. Alternative strategies exist, such as drilling. Let's examine most of these machining techniques extensive. The CNC turning technique is considered a subtractive production method. On top of that, it calls for maintaining bars of product, usually why not try this out plastic or steel, in placement and then turning a reducing device to eliminate areas of the product as the material is transformed.

These approaches are similarly essential and produce components with high accuracy and consistent quality. The processes aid boost the overall quality of the machined motorcycle components.

All About Motorcycle Parts New Zealand Specialists